What are the commonly used equipment for bending processing in sheet metal fabrication?

Category:

News

Author:

Source:

Published:

2025/09/05

Summary:

Bending processing in sheet metal fabrication is a crucial part of the manufacturing process. The equipment and technology involved are vital to ensuring product quality and processing efficiency.

Bending processing in sheet metal fabrication is a crucial part of the manufacturing process. The equipment and technology involved are vital to ensuring product quality and processing efficiency. Below are some common sheet metal bending processing equipment:

1. There are various types of bending machines, such as manual press brakes, semi-automatic press brakes, and fully automatic press brakes.They can perform precise bending according to different materials and thicknesses, with convenient adjustments to meet diverse production requirements.

2. CNC Bending Machine: This is a highly automated bending equipment that can control parameters such as bending angle and depth through programming.CNC bending machines are suitable for mass production, capable of enhancing production efficiency and product quality.

3. Mechanical Presses: For certain large or special-material sheet metal components, mechanical presses may be required for bending operations.This equipment can provide tremendous pressure, ensuring that even relatively hard materials can be bent smoothly.

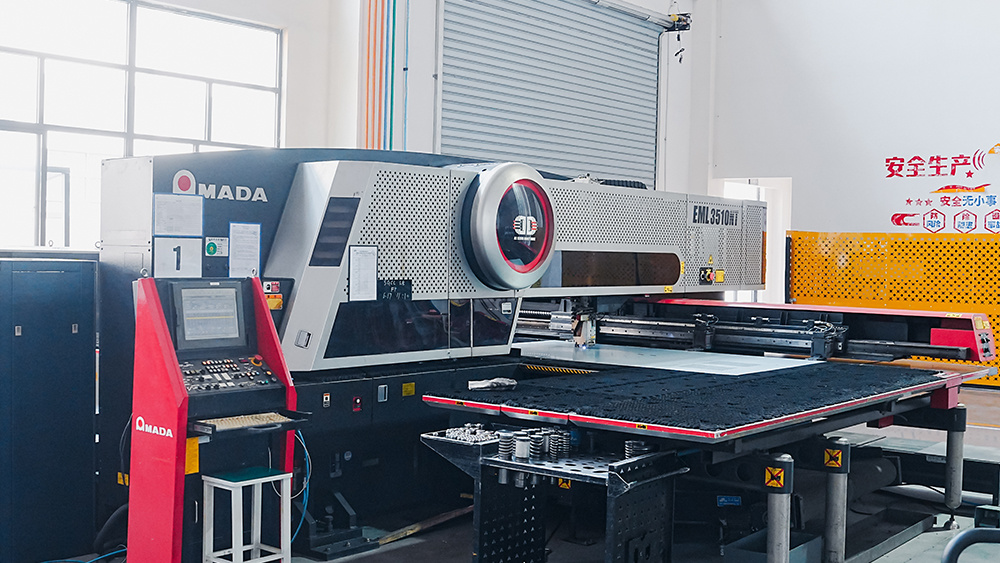

4. Laser Cutting Machine: Although primarily used for cutting, under certain circumstances, it can also be employed for precise bending.Their high precision and efficiency make them ideal processing equipment for complex-shaped sheet metal components.

5. Stamping Press: Punch presses are primarily used for forming and bending metal sheets. It can generate tremendous pressure through molds to achieve precise bending of materials.

6. Folding Machine: For smaller or thinner sheet metal parts, a folding machine may be utilized. This equipment features a compact structure and simple operation, making it suitable for small-scale production.

7. Auxiliary Equipment: Additionally, there are auxiliary devices used in sheet metal bending processes, such as dies, fixtures, and measuring tools. Although these devices do not directly participate in the bending, they are crucial for ensuring bending quality and efficiency.

When selecting bending equipment, factors such as the material, thickness, production scale of the sheet metal, and budget must be considered. Different equipment varies in processing efficiency, precision, and cost, so selection should be based on actual needs. Meanwhile, proper operation and maintenance of these devices are crucial to ensuring bending quality and extending equipment lifespan.

In summary, the bending process in sheet metal fabrication relies on various specialized equipment, which collectively guarantee the quality and precision of sheet metal components, meeting the demands across different fields.

Keyword:

Xinqisheng

Precision Sheet Metal

Previous Page

Related News

2025-09-05

Located in the Baoying Economic Development Zone, Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd. is a private enterprise specializing in the manufacturing of high-end precision sheet metal. With over two decades of technological accumulation and innovative breakthroughs, the company has not only achieved a remarkable transformation from traditional processing to intelligent manufacturing, gradually building its own business empire, but also become a key supplier of customized high-end sheet metal services for industries such as nuclear power, medical, and rail transportation.

2025-09-05

Decisive Finale for the "14th Five-Year Plan": Counties Compete for Industrial Strength, New Quality Productive Forces Emerge in Hundreds of Enterprises

Xinqi Precision Sheet Metal: Leading the Sheet Metal Industry with Technological Innovation

2025-09-05

Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd., located in the development zone, is a private enterprise specializing in the manufacturing of special corrosion-resistant sheet metal. Through profound expertise in sheet metal fabrication technology and over two decades of dedicate refinement, the company has evolved from traditional processing to high-end manufacturing.

What are the commonly used equipment for bending processing in sheet metal fabrication?

2025-09-05

Bending processing in sheet metal fabrication is a crucial part of the manufacturing process. The equipment and technology involved are vital to ensuring product quality and processing efficiency.