Sheet Metal Fabrication Process Flow

Category:

News

Author:

Source:

Published:

2025/09/05

Summary:

Sheet metal processing and manufacturing is a process involving the processing and manufacturing of sheet metal. Its workflow encompasses the entire process from raw materials to finished products, widely applied in fields such as machinery, electronics, and construction. The following provides a detailed introduction to the process flow of sheet metal fabrication and manufacturing.

Sheet Metal Fabrication Process Flow

I. Overview

Sheet metal processing and manufacturing is a process involving the processing and manufacturing of sheet metal. Its workflow encompasses the entire process from raw materials to finished products, widely applied in fields such as machinery, electronics, and construction. The following provides a detailed introduction to the process flow of sheet metal fabrication and manufacturing.

II. Process Flow

1. Raw Material Preparation

First, select metal sheets that meet the requirements, such as stainless steel, carbon steel, aluminum plates, etc. Based on product requirements and design, cut them into appropriate dimensions.

2. Cutting

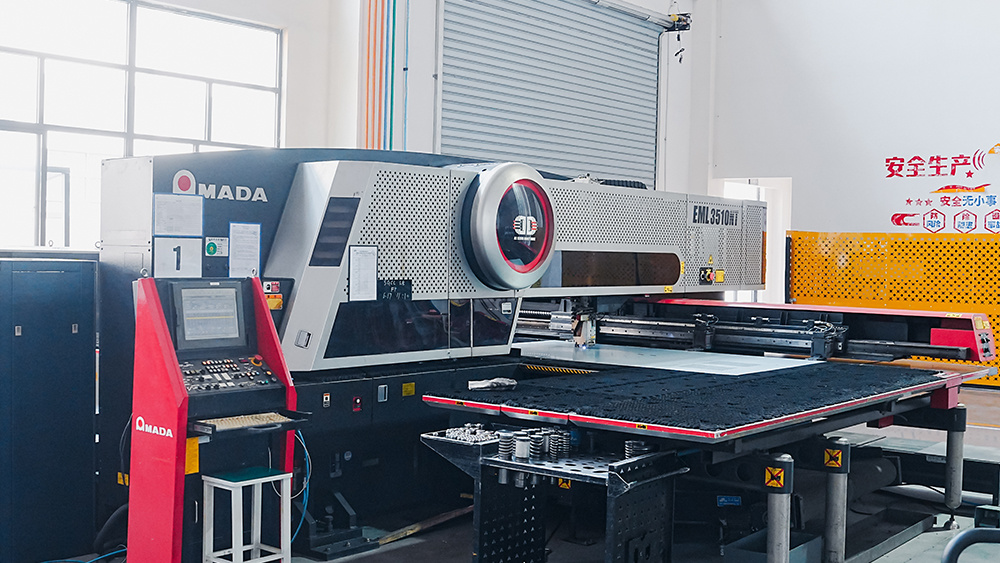

Utilize equipment such as CNC cutting machines, laser cutters, or flame cutters to perform precise cutting according to the design drawings.

3. Bending

Utilize a bending machine to bend metal sheets, achieving the desired angles and shapes.

4. Welding

Employ welding processes such as manual arc welding, Tungsten Arc Welding, laser welding, etc., to join the components together.

5. Surface Treatment

Includes deburring, cleaning, painting, rust-proofing, etc., to enhance product appearance quality and service life.

6. Quality Inspection

Conduct quality inspections at each production stage to ensure products meet design specifications.

7. Assembly

Assemble all components together to form the complete product.

8. Debugging and Testing

Conduct performance debugging and testing on final products to ensure stable and reliable performance.

9. Packaging and Shipping

Upon completion of all aforementioned processes, the products are packaged for shipment to customers.

III. Precautions

During sheet metal fabrication, special attention must be paid to safe operations to prevent workplace injuries. Simultaneously, product quality must be ensured by strictly adhering to design requirements and production processes.

IV.Summary

The sheet metal fabrication process encompasses the entire workflow from raw material preparation to finished product packaging. Each step requires strict operation to ensure product quality. With the advancement of technology, sheet metal processing techniques continue to innovate, providing robust support for enhancing product quality and efficiency. Enterprises engaged in sheet metal processing and manufacturing should continuously learn and master new technologies to adapt to market demands.

Keyword:

Xinqisheng

Precision Sheet Metal

Previous Page

Related News

2025-09-05

Located in the Baoying Economic Development Zone, Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd. is a private enterprise specializing in the manufacturing of high-end precision sheet metal. With over two decades of technological accumulation and innovative breakthroughs, the company has not only achieved a remarkable transformation from traditional processing to intelligent manufacturing, gradually building its own business empire, but also become a key supplier of customized high-end sheet metal services for industries such as nuclear power, medical, and rail transportation.

2025-09-05

Decisive Finale for the "14th Five-Year Plan": Counties Compete for Industrial Strength, New Quality Productive Forces Emerge in Hundreds of Enterprises

Xinqi Precision Sheet Metal: Leading the Sheet Metal Industry with Technological Innovation

2025-09-05

Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd., located in the development zone, is a private enterprise specializing in the manufacturing of special corrosion-resistant sheet metal. Through profound expertise in sheet metal fabrication technology and over two decades of dedicate refinement, the company has evolved from traditional processing to high-end manufacturing.

What are the commonly used equipment for bending processing in sheet metal fabrication?

2025-09-05

Bending processing in sheet metal fabrication is a crucial part of the manufacturing process. The equipment and technology involved are vital to ensuring product quality and processing efficiency.