What are the key quality management points for sheet metal fabrication manufacturers?

Category:

News

Author:

Source:

Published:

2025/09/05

Summary:

Sheet metal fabrication is an industry involving precision manufacturing and process control, where product quality directly impacts the performance and safety of the final product.

Key Points of Quality Management in Sheet Metal Processing

Sheet metal processing is an industry that involves precision manufacturing and process control, where product quality directly impacts the performance and safety of the final product. Therefore, for sheet metal fabrication plants, quality management is the key to ensuring competitiveness, customer satisfaction, and sustainable development. The following are the key points of quality management for sheet metal fabricators:

I. Raw Material Control

Rigorous screening of raw materials constitutes the initial step in quality management. It is essential to ensure that the quality and specifications of raw materials meet production requirements, avoiding the use of substandard or counterfeit materials. Establish long-term cooperative relationships with suppliers and conduct regular evaluations to ensure the stability and reliability of raw materials.

II. Process Formulation and Optimization

Develop detailed process flows, specifying operational norms and standards for each production stage. For new product processing, conduct trial production to verify and optimize the manufacturing processes. Ensure employees are familiar with and adhere to the process flow to minimize human errors.

III. Equipment Maintenance and Calibration

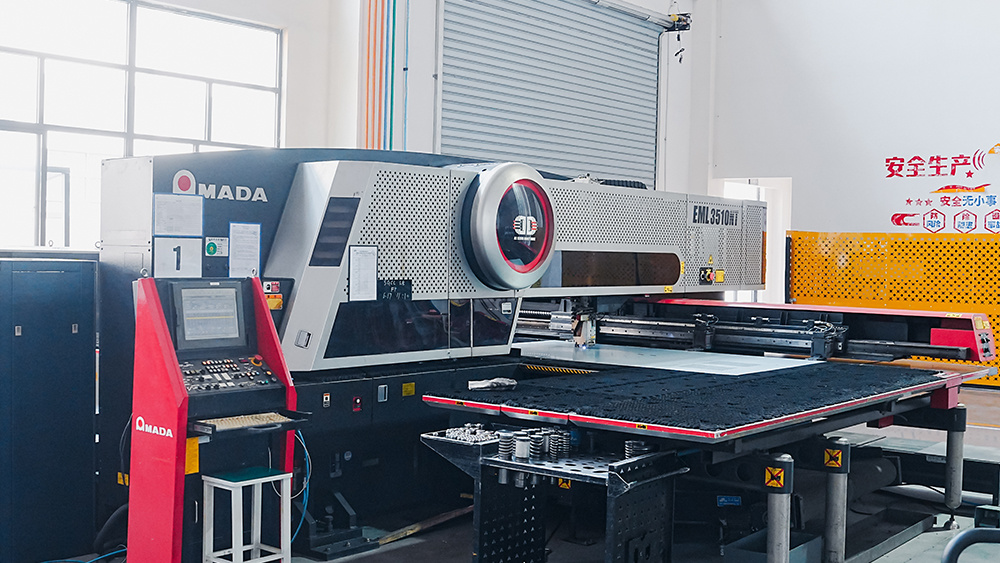

Ensure production equipment remains in optimal working condition by conducting regular maintenance and servicing. Perform regular calibration of critical equipment to ensure production accuracy. Timely upgrade outdated equipment to prevent compromising product quality.

IV. Personnel Training and Assessment

Conduct regular training for employees to enhance their skill levels and quality awareness. Establish an assessment mechanism to evaluate employees' production skills and quality control capabilities, ensuring they meet job requirements.

V. Quality Inspection and Monitoring

Establish stringent quality inspection standards, with focused testing on critical components of the products. Adopt advanced testing equipment and methodologies to ensure product quality and performance meet requirements. Implement real-time monitoring of the production process to promptly identify and rectify issues.

VI. Continuous Improvement

Establish a quality information feedback mechanism to collect customer feedback and market intelligence, enabling continuous improvement of product quality. Analyze and summarize issues arising during the production process, identify root causes, and implement corrective measures for improvement.

VII. Quality Management System Construction

Establish and improve the quality management system, integrating quality control throughout the entire production process. Through the certification and implementation of the quality management system, ensure product quality meets international standards and customer requirements.

In summary, the quality management of sheet metal fabrication manufacturers involves multiple aspects, requiring full participation from all employees, with strict controls implemented at every stage from raw materials to production and inspection. Only in this way can product quality be ensured, competitiveness enhanced, and customer trust earned.

Keyword:

Xinqisheng

Precision Sheet Metal

Previous Page

Related News

2025-09-05

Located in the Baoying Economic Development Zone, Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd. is a private enterprise specializing in the manufacturing of high-end precision sheet metal. With over two decades of technological accumulation and innovative breakthroughs, the company has not only achieved a remarkable transformation from traditional processing to intelligent manufacturing, gradually building its own business empire, but also become a key supplier of customized high-end sheet metal services for industries such as nuclear power, medical, and rail transportation.

2025-09-05

Decisive Finale for the "14th Five-Year Plan": Counties Compete for Industrial Strength, New Quality Productive Forces Emerge in Hundreds of Enterprises

Xinqi Precision Sheet Metal: Leading the Sheet Metal Industry with Technological Innovation

2025-09-05

Jiangsu Xinqisheng Precision Sheet Metal Co., Ltd., located in the development zone, is a private enterprise specializing in the manufacturing of special corrosion-resistant sheet metal. Through profound expertise in sheet metal fabrication technology and over two decades of dedicate refinement, the company has evolved from traditional processing to high-end manufacturing.

What are the commonly used equipment for bending processing in sheet metal fabrication?

2025-09-05

Bending processing in sheet metal fabrication is a crucial part of the manufacturing process. The equipment and technology involved are vital to ensuring product quality and processing efficiency.